China Ningbo Bestway Magnet Co.,Ltd. specialized in producing and supplying various magnets, bonded injection magnet, bonded injection magnets and magnetic products for more than 8 years, with our own factories in China. Our annual production capacity is over 5,000 tons about various magnets. Our products are sold over 40 countries around the world. With high quality management term, we are proud to obtain ISO9002. In all our selling products, bonded injection magnet, bonded injection magnets, bonded ferrite injection magnet shown in the brochure, we especial recommend to sell thin and small dimensions magnets. We also have a excellent team to provide various design about magnetic assembly appliance. For all, We persist in providing superior quality, competitive prices as well as prompt delivery. Based on this strong background for many years. We serve our customers sincerely while they treat us as their trustful friends. |

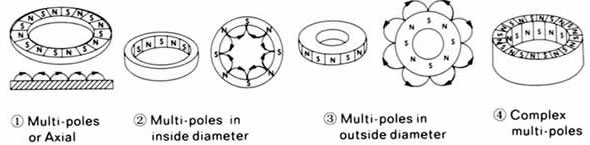

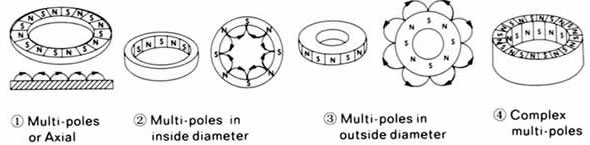

Characteristics & Application of Injection Bonded Magnet

Applications: Copier and laser printer rolls

Permanent motor magnets

(rotors & other components)

Magnetic rings for aerodynamic component

Color Monitor/TV purity convergence magnet

Bonders: PA6, PA12, PPS.

Characteristics:Having high dimensional precision

Versatile shapes and specification

Impact-resistant.advanced surface treatment technology,effectively protect.

Integrated forming

|

| |

Magnetic properties Of Injection Ferrite Bonded Magnet

TYPE NO. |

Binder |

Magnet

Material |

Br

(mT)

Gs |

Hcb

(kA/m)

Oe |

Hcj

(kA/m)

Oe |

BH(max)

(kJ/m3)

MGOe |

Density

(g/cm3) |

Usage |

FBP-1210 |

Nylon6 |

Baferrite

Srferrite |

65~75

650~750 |

40~48

503~603 |

190~230

2400~2890 |

0.6~0.8

0.07~0.1 |

2.4~2.5 |

PCM for TV、Monitor |

FBP-1211 |

Nylon6

Nylon12 |

Baferrite

Srferrite |

110~130

1100~1300 |

70~85

880~1068 |

190~230

2400~2890 |

1.5~3.0

0.19~0.38 |

2.7~3.2 |

Isotropic injection magnet |

FBP-1212 |

Nylon6

Nylon12 |

Baferrite

Srferrite |

130~150

1300~1500 |

85~105

1070~1320 |

190~230

2400~2890 |

3.0~4.2

0.38~0.53 |

3.2~3.7 |

Isotropic injection magnet |

FBP-1213 |

Nylon6

Nylon12 |

Baferrite

Srferrite |

210~240

2100~2400 |

120~170

1510~2140 |

160~230

2010~2890 |

7.0~12.0

0.88~1.5 |

3.0~3.5 |

Anisotropic injection magnet |

FBP-1214 |

Nylon6

Nylon12 |

Baferrite

Srferrite |

250~260

2500~2600 |

164~174

2060~2190 |

210~230

2640~2890 |

11.9~12.5

1.5~1.57 |

3.35~3.55 |

Anisotropic injection magnet |

FBP-1215 |

Nylon6

Nylon12 |

Srferrite |

250~260

2500~2600 |

174~184

2190~2310 |

230~280

2890~3520 |

12.1~12.7

1.52~1.6 |

3.35~3.55 |

Anisotropic injection magnet |

FBP-1216 |

Nylon6

Nylon12 |

Srferrite |

250~260

2500~2600 |

184~194

2310~2440 |

280~320

3520~4000 |

12.3~12.9

1.55~1.62 |

3.35~3.55 |

Anisotropic injection magnet |

FBP-1217 |

Nylon6

Nylon12 |

Srferrite |

270~280

2700~2800 |

170~190

2140~2390 |

210~230

2640~2890 |

14.3~14.9

1.8~1.87 |

3.5~3.65 |

Anisotropic injection magnet |

FBP-1218 |

Nylon6

Nylon12 |

Srferrite |

270~280

2700~2800 |

180~200

2260~2390 |

230~280

2890~3520 |

14.4~15.0

1.80~1.88 |

3.5~3.65 |

Anisotropic injection magnet |

FBP-1219 |

Nylon6

Nylon12 |

Srferrite |

270~280

2700~2800 |

190~200

2390~2510 |

280~320

3520~4000 |

14.5~15.1

1.82~1.89 |

3.5~3.65 |

Anisotropic injection magnet |

FBP-1220 |

Nylon6

Nylon12 |

Srferrite |

275~285

2750~2850 |

180~200

2260~2510 |

210~250

2640~3140 |

14.7~15.5

1.85~1.95 |

3.60~3.70 |

Anisotropic injection magnet |

FBP-1221 |

Nylon6

Nylon12 |

Srferrite |

285~295

2850~2950 |

190~210

2390~2640 |

210~250

2640~3140 |

15.5~17.0

1.95~2.14 |

3.65~3.75 |

Anisotropic injection magnet |

FBP-1222 |

PPS |

Srferrite |

245~265

2450~2650 |

170~180

2140~2260 |

210~250

2640~3140 |

11.0~13.0

1.38~1.63 |

3.48~3.65 |

Anisotropic injection magnet |

|

| |

Physical Characteristics of Injection Ferrite Magnet

NO. |

Density

(g/cm3) |

Tension Strength (Kg/cm2) |

Bend Strength (Kg/cm2) |

Impact Strength (Kg*cm/cm2) |

Hardness

(Rsc) |

Water Absorption (%) |

Heat Distortion Temp(oC ) |

FBP-1210 |

2.5~2.7 |

630 |

1000 |

25.0 |

102 |

0.07 |

110 |

FBP-1211 |

2.7~3.0 |

630 |

1100 |

25.0 |

103 |

0.07 |

110 |

FBP-1212 |

2.6~2.9 |

630 |

1100 |

24.0 |

103 |

0.07 |

115 |

FBP-1213 |

3.0~3.5 |

630 |

1100 |

23.0 |

104 |

0.07 |

113 |

FBP-1214 |

3.1~3.5 |

630 |

1200 |

23.0 |

116 |

0.07 |

117 |

FBP-1215 |

3.35~3.55 |

630 |

1150 |

23.0 |

110 |

0.07 |

117 |

FBP-1216 |

3.35~3.55 |

600 |

1150 |

21.0 |

112 |

0.05 |

118 |

FBP-1217 |

3.5~3.65 |

550 |

1200 |

20.0 |

112 |

0.05 |

120 |

FBP-1218 |

3.5~3.65 |

550 |

1200 |

19.0 |

114 |

0.05 |

120 |

FBP-1219 |

3.5~3.65 |

500 |

1200 |

17.0 |

115 |

0.04 |

125 |

FBP-1220 |

3.60~3.70 |

470 |

900 |

12.0 |

115 |

0.04 |

128 |

FBP-1221 |

2.65~3.75 |

450 |

800 |

12.0 |

115 |

0.04 |

135 |

FBP-1222 |

3.48~3.65 |

430 |

800 |

8.5 |

115 |

0.04 |

137 |

|

| |

Physical&Magnetic properties Of Injection NdFeB Bonded Magnet

P/N |

NBI-4 |

NBI-6 |

NBI-6M |

NBI-8 |

Br (mT) |

400-490 |

490-570 |

480-560 |

570-630 |

bHc(kA/m) |

256-312 |

312-384 |

336-400 |

382-430 |

iHc(kA/m) |

576-736 |

640-800 |

960-1360 |

680-840 |

(BH)max(kJ/m3) |

28-36 |

40-56 |

44-60 |

60-68 |

Recoil permeability |

1.1-1.22 |

1.1-1.22 |

1.1-1.22 |

1.1-1.22 |

Recoil temperature coeffiient of Br. (%/) |

-0.10

(15-100) |

-0.09

(15-100) |

-0.10

(15-100) |

-0.10

(15-100) |

Magnetizing field (Ka/m) |

1592 |

1592 |

1990 |

1592 |

Density(g/cm3) |

4.0-4.5 |

4.5-5.5 |

5.0-5.5 |

5.0-5.5 |

Ring crushing strength constant (N/mm2) |

> 78 |

> 78 |

> 78 |

> 78 |

|

| |

Physical & Magnetic properties Of Injection AlNiCo Bonded Magnet

TYPE NO. |

Binder |

Magnet

Material |

Br

(mT)

Gs |

Hcb

(kA/m)

Oe |

Hcj

(kA/m)

Oe |

BH(max)

(kJ/m3)

MGOe |

Density

(g/cm3) |

Usage |

PAI-1 |

Nylon6 |

AlNiCo |

95~105

950~1050 |

30~35

377~440 |

50~56

628~704 |

0.8~1.1

0.1~0.14 |

2.75~2.85 |

PCM for TV、Monitor |

PAI-2 |

Nylon6 |

AlNiCo |

44~50

440~500 |

20~24

251~302 |

50~56

628~704 |

0.25~0.35

0.03~0.04 |

2.0~2.3 |

PCM for TV、Monitor |

|

| |

Physical &Magnetic properties Of Injection Smco Bonded Magnet

P/N |

SCI-3 |

SCI-8 |

Br (mT) |

300-400 |

550-680 |

bHc(kA/m) |

199-279 |

334-462 |

iHc(kA/m) |

716-1194 |

716-1194 |

(BH)max(kJ/m3) |

20-28 |

48-64 |

Recoil permeability μ5 |

1.05-1.1 |

1.05-1.1 |

Recoil temperature coeffiient of Br. (%/oC) |

-0.04

(15-100oC) |

-0.04

(15-100oC) |

Magnetizing field (Ka/m) |

≥2786 |

≥ 2786 |

Density(g/cm3) |

3-6 |

4-6 |

Ring crushing strength constant (N/mm2) |

> 76 |

> 76 |

|

| |

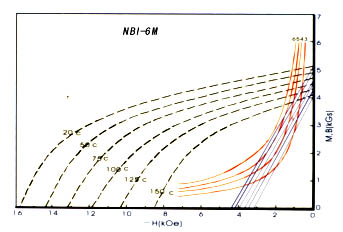

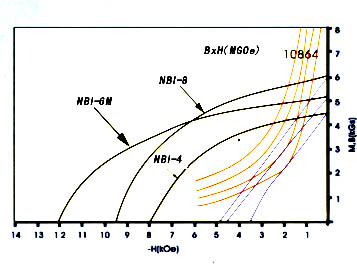

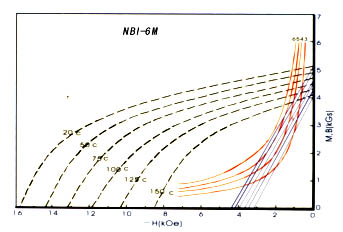

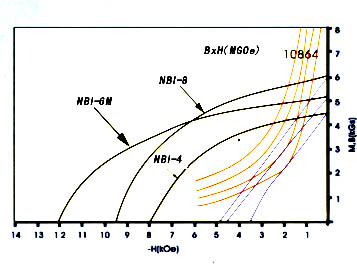

Typical Demagnetization curve of Injection NdFeB Magnet |

Temperature Characteristic Curve Of Injection NdFeB Magnet

|

| |

Inspection standard for permanent magnet Inspection standard for permanent magnet

Purchasing Guide Purchasing Guide

Permanent magnet supply direction Permanent magnet supply direction

Surface protection and surface coating for the permanent magnet Surface protection and surface coating for the permanent magnet

Quality warranty Quality warranty

Safety principle for manual operation of permanent magnet Safety principle for manual operation of permanent magnet |

| |

|

|

Inspection standard for permanent magnet

Inspection standard for permanent magnet

Purchasing Guide

Purchasing Guide Permanent magnet supply direction

Permanent magnet supply direction Surface protection and surface coating for the permanent magnet

Surface protection and surface coating for the permanent magnet

Quality warranty

Quality warranty Safety principle for manual operation of permanent magnet

Safety principle for manual operation of permanent magnet